IPS – International Partners in Steel

KALTENBACH in-house exhibition

News

Information about the next IPS

The continuing difficult situation due to the Covid-19 pandemic has already prevented us from holding the IPS last time. Due to the continued restricted travel activities as well as various changes and renovations at the Lörrach site, the exhibition cannot be implemented as usual and to its full extent.

Due to this, we regret to inform that after long deliberations we had to decide against an IPS 2023.

We remain aware of the importance and scope of our in-house exhibition. Should the next IPS take place again, you will be informed about it here, or also under our news on our website https://www.kaltenbach.com/en/.

KALTENBACH thanks you very much for your interest and we look forward to welcoming you again at the next International Partners-in-Steel!

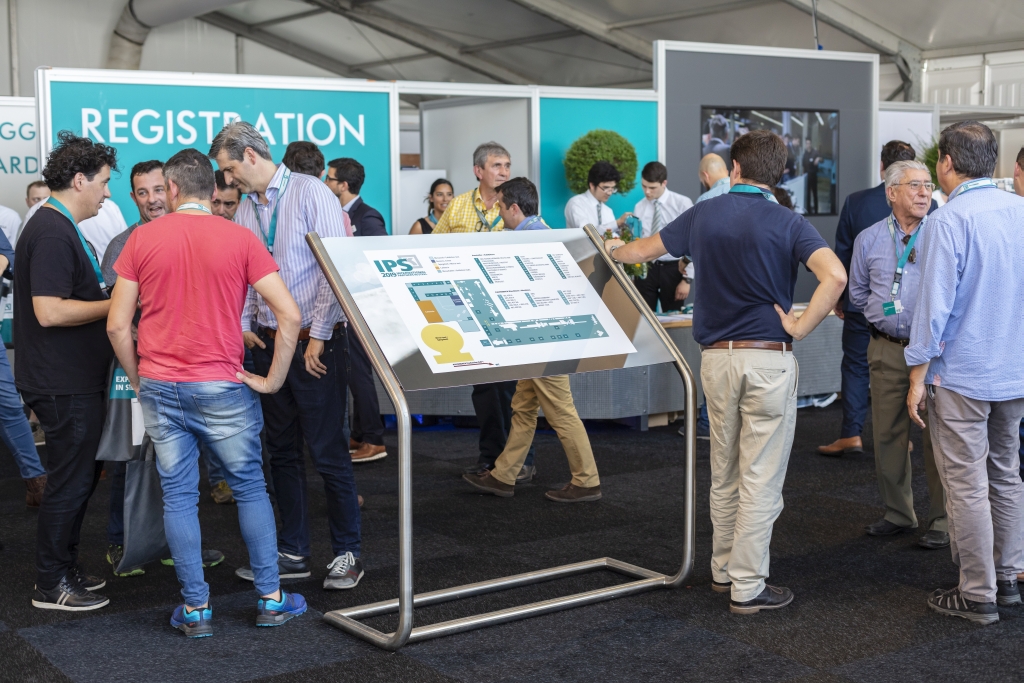

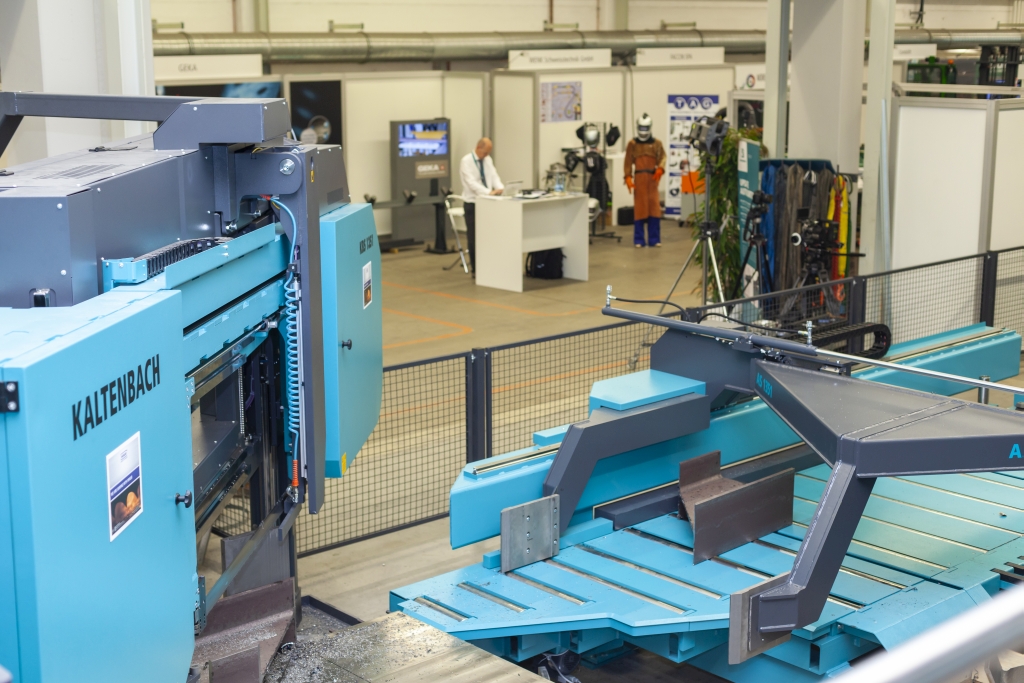

IPS 2019 Review

IPS 2019 - The Movie

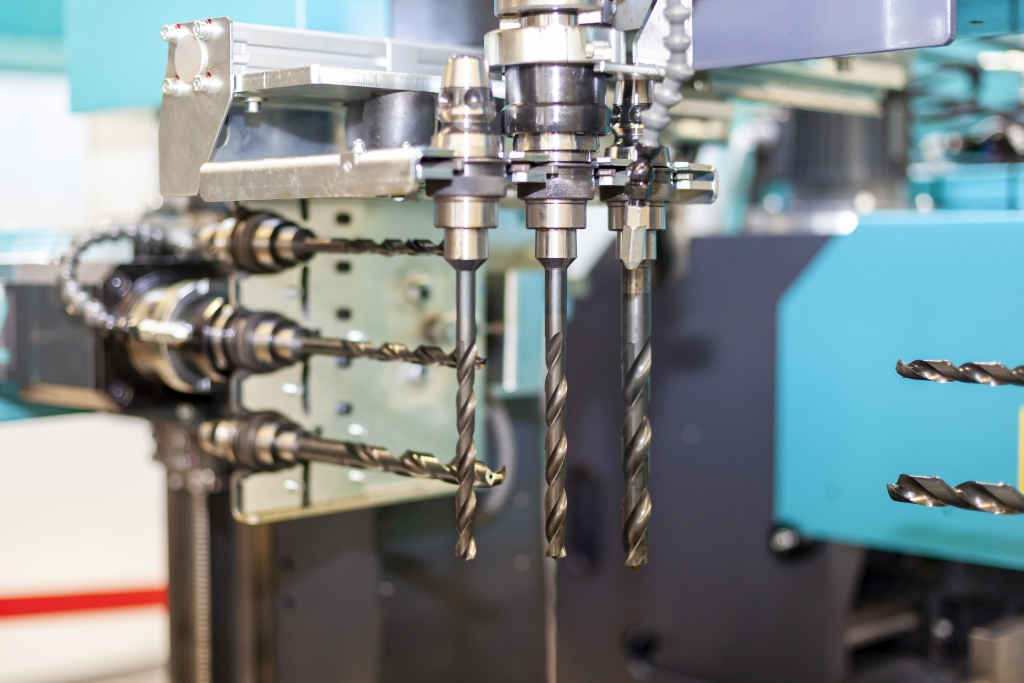

Convince yourself at the IPS of the company as system provider, including machinery, partnerships and international service presence.

KALTENBACH – THE SYSTEM PROVIDER

Many thanks to our exhibitors 2019

Deutsch

Deutsch